Testing the Magnet

by Paul Rivenberg/MIT PSFC. September 2021

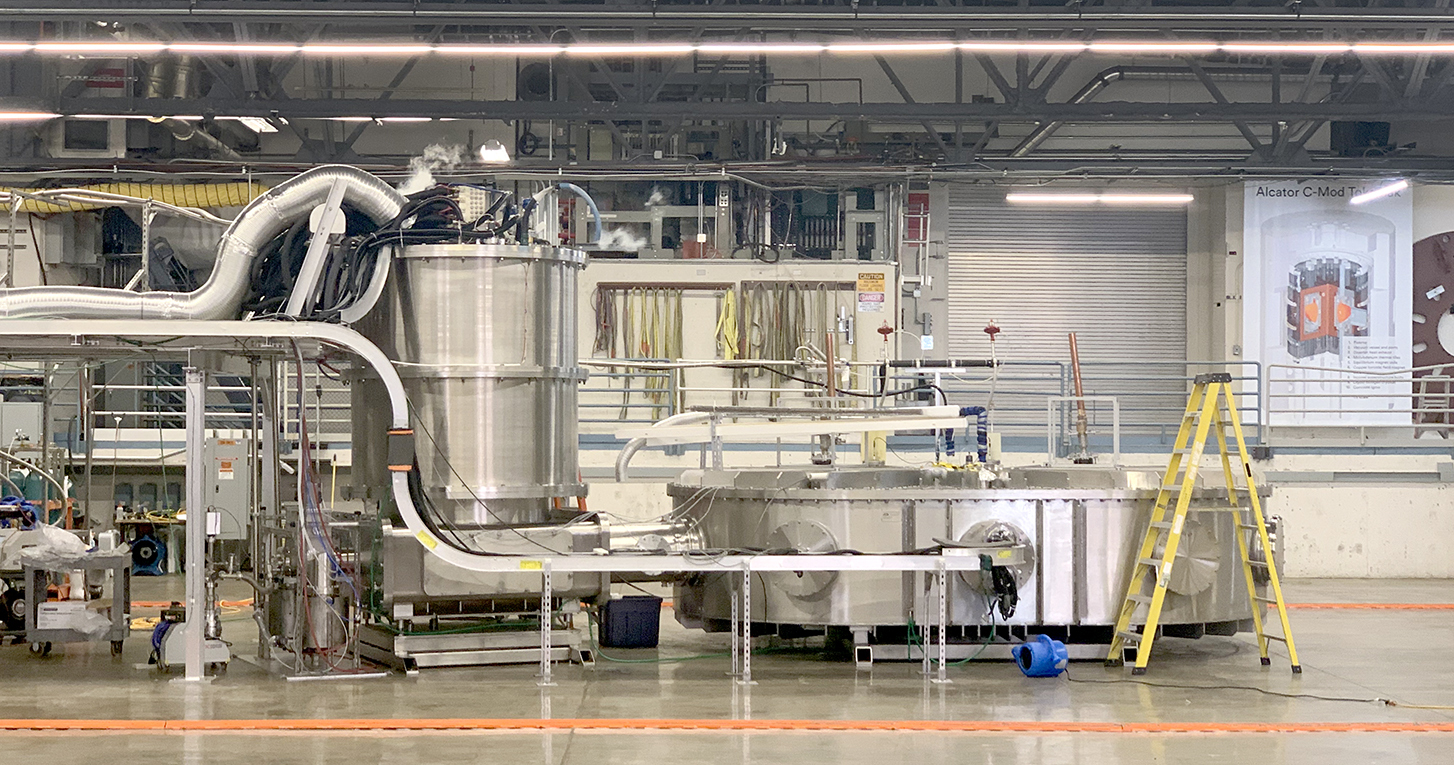

Following three years of intense research, development and manufacturing, the Toroidal Field Model Coil (TFMC) is ready for testing. This scaled prototype for the high-temperature superconducting (HTS) magnets designed to contain fusion reactions in SPARC will be enclosed in a cryostat, cooled to operating conditions and charged. A successful test will demonstrate that we have the technology in hand to construct TF coils for SPARC.

Senior Research Scientist, Brian LaBombard, the technical lead for SPARC’s TF design, describes the TFMC as a D-shaped coil that is close to the full-sized TF coil in linear dimensions, constructed with a design that is more or less identical to what will be used for the SPARC TF coil. The proprietary design allows the magnet to be compact but robust, providing room for coolant channels – all necessary to attain a 12 tesla magnetic field in the plasma core of SPARC – while at the same time handling the intense neutron heat loads that will result from Q > 1.

LaBombard explains that the TFMC must push beyond the SPARC TF coil performance in one important aspect – it must attain 40 kA in the superconductor compared to 31.25 kA. This is necessary because the primary goal of the TFMC is to demonstrate that this new magnet technology can attain 20 tesla (T) in the winding pack, just like it will be in the SPARC TF. However, the TFMC will not have other coils nearby to assist, as would be the case for TF coils in an operating SPARC.

Attaining 20T requires being able to predict and know that the HTS tape critical current performance – combined with the amount of HTS tape built into the coil – will be sufficient to maintain superconductivity, control dissipation and leakage currents and to avoid quench; it requires structures that can accommodate forces and strains on the tape, maintain 20 bar helium pressures and cryogenic temperatures of 20K; it requires excellent bus work; it requires integrated infrastructure, instrumentation, and controls to operate the magnet.

The successful test is a direct, at-scale demonstration of novel HTS magnet technology that translates to large bore, high field magnets for SPARC. It is also a validation of first principles understanding of how this new magnet technology works. Researchers, understanding why it works and how to optimize magnet performance, will be ready to build SPARC.